2nd International Conference on Food Science and Bioprocess Technology

October 1-2, 2018 Frankfurt, Germany

Membrane Separation Processes and their Application in Food, Beverage and Herbal Industries

Swiss German University, Indonesia

Membrane technology has gained more application for the separation and purification processes in various industries, including food, beverage and herbal industries. There are two categories of membrane based on the material used to prepare it, namely polymer membranes and ceramic membranes, each of them having advantageous and disadvantageous. Polymer membranes are cheaper in price compared to the ceramic membranes, however ceramic membranes show a better stability against chemicals and can be applied at a higher temperature. Here, the development of various membranes both polymer and ceramic, and their application for food, beverage and herbal industries are presented. An ultrafiltration polymer membrane was developed using beverage plastic bottles as the source of the membrane polymer material. The membrane was tested for an ultrafiltration experiment and showed a rejection of particles with a molecular weight about 20,000 Dalton. The utilization of plastic bottle waste as the raw material to prepare the membrane also becomes a solution for the environmental problem caused by the large amount of disposed plastic bottle waste. Further, the development of a ceramic microfiltration membrane from kaolin and alumina is also presented. The result of the microfiltration experiment showed that the ceramic membrane had a high permeate flux and a 100% rejection of microorganism, showing that the membrane has a potential to applied for purification and sterilization processes in food, beverage and herbal industries. Some examples of the application of the membranes for the sterilization of extract solutions such as butterfly pea extract and coffee silver skin extract solutions are presented.

Keywords: Membrane, microfiltration, ultrafiltration, food, beverage, herbal, sterilization

Biography:

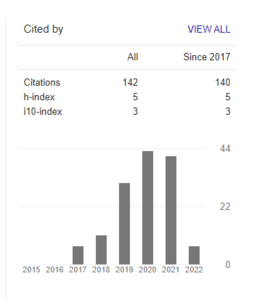

Samuel P Kusumocahyo is a lecturer and researcher in the Faculty of Life Sciences and Technology, Swiss German University, Indonesia. His current position is the Dean of the faculty covering study programs of Food Technology, Sustainable Energy & Environment, Pharmaceutical Engineering, and Biomedical Engineering. He received Bachelor & Master Degree (Dipl.-Ing) in Chemical Engineering from Aachen University (RWTH Aachen), Germany, and Doctoral Degree in Chemical Engineering & Environmental Science from Shizuoka University, Japan. He is an expert in the separation processes using membranes which are widely applied for food & beverage industries, waste treatment, water purification, chemical processes, biofuels production, etc. His recent research activities include the optimization of extraction processes of various Indonesian natural plants for the development of new source of bioactive compounds.