Review Article

Introduction to Wax Deposition

Ministry of Higher Education and Scientific Research, Iraq

*Corresponding author: Muhammad Ali Theyab, Ministry of Higher Education and Scientific Research, Iraq, E-mail: theyabm@lsbu.ac.uk

Received: April 10, 2018 Accepted: May 2, 2018 Published: May 7, 2018

Citation: Theyab MA, Yahya SY. Introduction to Wax Deposition. Int J Petrochem Res. 2018; 2(1): 126-131. doi: 10.18689/ijpr-1000122

Copyright: © 2018 The Author(s). This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

This work is presents in brief an introduction to wax deposition process to give a general understand of this problem because of arising the challenges of growing wax deposition in the hydrocarbon pipelines by increasing production in the cold environment due to increasing demand for energy. Background and identification of wax deposition problem in the hydrocarbon pipelines are presented. Mitigation methods are used to address this problem, such as chemical, mechanical and thermal methods, but despite the available inhibition methods, many oil companies currently suffer from wax deposition problems and are still looking for a good solution to solve this issue. This research presents some of the case studies of wax deposition around the world and the methods followed to mitigate wax deposition of each case study.

Numerous researchers have used various different types of chemical inhibitors, such as polyacrylate polymer, copolymer esters, polyethylene, olefin/ester copolymers, ethylene/vinyl acetate copolymers, ester/vinyl acetate copolymers, polymethacrylates, alkyl phenol resins, xylene and toluene, to studying their influence on the rheology of crude oil and to evaluate the suitable inhibitor for the waxy crude oil that provides the desired results in preventing wax deposition.

The decent understanding and managing of wax deposition phenomena before it happens is strongly required in order to overcome the challenges in production and transportation of pipelines in the cold environment.

Keywords: Wax deposition, Problem identification, Case study, Chemical inhibitors, Spiral flow.

Introduction

The world demand for energy has led oil companies to expand their operations in cold environments such as the offshore deepwater and onshore for more reservoirs. During hydrocarbon production in the cold environment, these oil companies are challenged by wax deposition problem building up on the pipe wall.

Crude oil is a complex mixture and contain a main components of saturates (paraffins/waxes), aromatics, asphaltenes, naphthenes and resins. The high molecular weight paraffin (wax) is naturally responsible for the problems during production and transportation in the hydrocarbon pipeline systems.

The accumulation of wax in the oil pipelines depends on the difference temperature between crude oil and pipe wall. There are two conditions should be available to occur wax deposition in the crude oil pipe. Those conditions are involved, the temperature of the crude oil close to the pipe wall should be less than the wax appearance temperature, and the pipe wall temperature must be lower than the oil temperature [1]. Wax deposition process is influenced and controlled by some factors, such as pipe wall temperature (inlet coolant temperature), flow rate, pressure drop, oil temperature, shear stress, recirculation time of crude oil and viscosity.

At the reservoirs, wax molecules are dissolved in the crude oil because of the temperatures range between (70 - 150 °C) and pressures range between (50-100MPa). Though, crude oil flows through the subsea pipeline resting on the cold environment of ocean floor at a temperature of 4°C, the temperature of oil in time decreases below its wax appearance temperature because of the heat losses to the surroundings [2].

Wax molecules start to precipitate out of the crude oil when the solubility of wax decreases drastically as the temperature decreases. Oil production in deep sea areas and cold environment onshore has increased significantly due to the high demand for energy.

The exploration and production technologies in deep sea areas have made deep water drilling economically feasible and the oil industry has drilled subsea oil wells as far as 160 miles away from the shore. As oil wells are developed further offshore, wax problems will become more severe and extensive due to the increased transportation lines on the cold ocean floor [3][2].

In 2015, the global offshore oil production reached 9.3 million barrels per day (including lease condensate and hydrocarbon gas liquids) from deepwater projects. Deepwater production has increased 25% from nearly 7 million b/d a decade ago. Shallow water has been somewhat less expensive and less technically challenging for operators to explore and drill, but changing economics and the exhaustion of some shallow offshore resources has helped to push producers to deepwater or, in some areas, ultra-deepwater (at depths of 1,500 meters or more) resources. The share of offshore production from shallow water in 2015 was 64%, the lowest on record [4].

This research is showing the challenges arising from the growing size of wax deposition in the hydrocarbon pipelines by increasing production in the cold environment. Therefore, some of case studies of wax deposition in the crude oil pipelines around the world are presented during this research. Many oil companies around the world used different techniques to reduce wax deposition in the pipelines such as chemical inhibitors, mechanical and thermal techniques. Most of the oil companies preferred the chemical inhibitors because it not needs to stop production.

Many researchers, as will see in this work, preferred chemical inhibitors in their research to reduce wax deposition. While, Theyab and Diaz (2016a, 2016b, 2016c) [5][6][7] were used the chemical inhibitors such as polyacrylate polymer (C16-C22), spiral flow, and the combination of the chemical inhibitor with the spiral flow to mitigate wax deposition. The spiral flow technique, raise interest in the possibility of increasing the shear rate to prevent wax deposition by mixing the wax crystals with the crude oil and prevent it to deposit on the pipe wall. Moreover, undertake a systematic study of inhibition of wax deposition using the effects of combination spiral flow with a chemical inhibitor to increase the effect of the mitigation process.

It can be concluded that, a fundamental understanding of wax deposition phenomena is highly required in order to overcome the challenges in production and transportation of pipelines in the cold environment.

Background of Wax Deposition

As early as 1928, wax deposition was reported as an issue that led to challenges in the crude oil production, transportation and storage [8]. In 1969, control of wax deposition in U.S. domestic production annually cost $4.5-$5 million. The problem of onshore wax deposition could be addressed by relatively simple methods, including the optimisation of the operating conditions (pipeline size, pressure, etc.), because of easy access and management of these resources. Heating of the onshore pipeline or mechanical removal of the wax deposit was used occasionally, but was generally not as prohibitive [8].

During the late twentieth century, as the problem of wax deposition became increasingly challenging, as the production of petroleum fluids shifted from onshore resources toward offshore reservoirs around the world [8]. In Lasmo oilfield in UK, the problem of wax deposition was so severe and frequent that led to abandon the entire field at a cost of over $100 million [1].

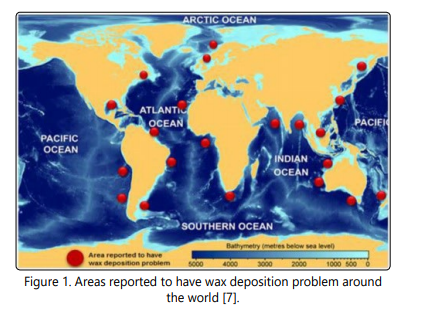

The severity of the wax problem needs evaluated in the design of every subsea and onshore development across the world, including the Gulf of Mexico, the North Slope, the North Sea, North Africa, Northeast Asia, Southern Asia and South America [8], see Figure 1; about the onshore including oil fields in North America, South America, Asia, Africa and Europe to estimate the cost of suitable remediation methods for wax deposition in the subsea pipeline and to avoid blockage.

Identification of Wax Deposition Problem

Wax deposition is, a public problem, a critical operational challenge and one of the main flow assurance problems in the oil industry around the world including the offshore and onshore oil fields. Wax deposition precipitates and deposit on the cold pipeline wall when the inner wall temperature falls below the wax appearance temperature and occurs when paraffin components in crude oil (alkanes with carbon numbers greater than 20) [1].

The formation of wax in the pipe during the fluid production from the bottom hole of the well to the surface can restrict the flow of crude oil, creating pressure abnormalities and causing an artificial blockage, as shown in Figure 2, leading to the reduction or even cessation of production [9]10[11][12][13][14]. Wax deposition also leads to formation damage near the wellbore, reduction in permeability, changes in the reservoir fluid composition and fluid rheology due to phase separation as wax solid precipitates [15].

Wax precipitation is impacted by several factors, such as: crude oil composition [16], flow rate, temperature gradient [17], pipe wall temperature (inlet coolant temperature), crude oil temperature, shear stress, production time and oil viscosity [18].

Wax deposition can be reduced or prevented by a chemical, mechanical, or thermal remediation method or by a combination of some of them [20]. If the wax mitigation methods not working well (e.g. insulation of pipeline, injection of wax inhibitor, or combination of both), a gel layer of wax will grows rapidly in thickness and obstructs the flow of oil because of flow restriction [1] [2]. Those elimination methods become increasingly significant as the oil industry operations expanded in deepwater to greater depths and distances in cold environments, which poses a great challenge to the industry [21a, 21b] [15]; [22][23][8].

Pigging is one of the most typically corrective methods used in the oilfields. In pigging, a pig passes through the pipeline to scrape off the wax deposit (pig is a solid material with the diameter less than the inner diameter of the pipe). Conversely, the pigging method cannot professionally be used without a proper wax deposition prediction. For example, pigs at times get stuck inside the pipeline in the presence of thick hard deposits making the situation worse, which occurred in a Gulf of Mexico pipeline. Production must be stopped in worst cases in order to replace the plugged portion of the line, which is estimated to cost approximately $40,000,000 per incident [8].

Alternative remediation method is to use a fused chemical reaction with controlled heat emission to mitigate wax deposition. However, in order to successfully use this technique, it is critical to know the thickness profile and the wax fraction of the deposit as a function of axial location and time. If this technique were to be used based on inaccurate information on the location of wax deposit and its wax fraction, there could be unwanted local high temperature in the pipeline due to the failure of re-dissolving wax deposit.

Successful wax deposition management will become more important in the future because new explorations and productions are being made farther offshore. The wax deposition management cost to the petroleum production industry is enormous and will increase both in terms of capital costs (e.g. preventive methods) and operating costs (e.g. corrective methods) [2].

Recently, three technologies are used around the world to mitigate wax deposition in the offshore and onshore oil, namely, pigging, thermal mitigation and wax inhibitors (chemical inhibitors. Most of the oil companies are using the wax inhibitors, as a main mitigation method to reduce wax, combined with pigging or thermal insulation.

Case Studies of Wax Deposition

In India offshore field to the west of India, the oil is transported through a 30-inch, 203-km pipeline from the offshore platform to a terminal on land. This crude oil has high wax content and a 30°C pour point. Given that the average seabed temperature is 22°C, pour point depressant (PPD) is injected. Specifically, 300 ppm/350 ppm of PPD is injected to achieve a pour point of 21°C/18°C and therefore maintain the flow of the oil. The subsea pipelines are regularly pigged. The cost of PPD injection alone is US$15 million/year. Whereas the use of PPD has maintained the oil flow, an on-going increase in the pipeline pressure has been observed over time. This indicates the presence of wax deposits in the subsea pipeline. According to a technical survey, approximately 20,000 m? of wax has already been deposited in the pipeline (which has a volume of 90,226 m?). A combination of PPD and dispersant was being considered to mitigate the wax deposition and therefore reduce the frequency of pigging [24].

Another case study, the Gannet oil field is located approximately 180 km east of Aberdeen in United Kingdom in a depth of about 90 m. The Gannet field is located 16 km northeast of the Gannet Alpha platform. Risers 31 and 32 carry oil from Gannet. The wax appearance temperature of this oil is approximately 35.5°C. Wax deposition in the subsea pipeline of Gannet was estimated to be around 21 m3 of wax had built up over a length of 8 km. An appropriate solvent was selected and injected at a rate of 0.6 m3/min. After solvent injection, an additional 480 m3/day of oil could be recovered. Also, the pigging method was used frequency with the inhibitors to remove wax deposition in Gannet oil field [25] [24].

The Power Play oil field is located in 706 m of water in Garden Banks block 28, Gulf of Mexico, and began production in 2008. It is a subsea tieback to a host facility with a subsea flow loop to enable oil circulation and pigging. The subsea architecture consists of two 10 km 4.5 × 7″ (pipe in pipe) PIP pipeline pigging loop systems with insulated steel catenary risers. The wax appearance temperature of the oil is 41.1°C, and the pour point ranges between -5°C and 19°C. Given that the WAT is high, wax deposition is possible. To mitigate this risk, a PIP system was applied to minimize heat loss from the oil. As observed in the northern and southern subsea pipelines during oil production, a simultaneous increase in the flowing bottomhole pressure and a drop in the oil production rate pointed to the possibility of partial plugging as a result of wax deposition in the pipeline. To mitigate this plugging, xylene solvent was injected into the pipelines at a rate of between 0.04 and 0.32 m3/min. This, combined with an increase in the pressure, was not able to remediate the wax deposition. Rather, the operation opted to switch the production zone from the lower zone to the higher zone to increase the flow rate. This increased the flow temperature to above the WAT and successfully mitigated wax deposition [26].

On another hand, Russian oil production is almost exclusively onshore and suffering from the problem of wax deposition such as padovskoe oil field, Mukhanovskoe oilfield, Petrukhnovskoe oil field and Urmanskoe oil field. Technological methods such as pigging and thermal insulation have been used combined with the chemical inhibitors to reach the highest efficiency to control the wax deposition in the pipelines. The chemical inhibitors that have been used to reduce wax deposition are includes surfactant (nanylphenol, synthanol), aromatic solvents (benzene, xylene, toluene), and aliphatic alcohol (butano, pentanol, hexanol) [27].

The wax deposition problem can occur even in the high temperature areas. For example, Kirkuk – Ceyhan crude oil pipeline between Iraq and Turkey is an example for the onshore pipelines that have wax deposition in winter season of the year. The average lowest temperature is about 2°C in winter between north of Iraq and Turkey, therefore, itʼs enough to form and deposit wax inside the pipeline. Kirkuk – Ceyhan crude oil pipeline is 40-inch in diameter and 1049 km long, of which 986-km pass through Turkish territory, and it had a capacity of 700,000 b/d. It was noticed that the wax mole fraction starts to rise with a value of 0.193 around 300 km from inlet and at the end of the pipeline reaches 0.2225. The pigging method and the aromatic solvents used to mitigate wax deposition in the pipeline [28].

Discussion

Many oil companies prefer chemical additives in analysing the economics of waxy crude oil production in cold environments, considering this the best solution to reduce wax deposition in pipelines due to chemical additives does not need to stop production for cleaning the pipe but it considers as an online mitigation method [8]. Some researchers are stating that there is currently no universal type of inhibitor can be used for all kinds of crude oil due to the varying properties of crude oils [29][24][30][31]. This is an investigation to understand the wax deposition problem, because of the universal inhibitor may solve the wax deposition problem and create more problems such as (corrosion) due to varying properties of crude oils and the different climate.

A universal solution would be a both convenient and cost effective response to the current demand. Presently, most of the companies have their personalised technique to tackle the wax deposition. This is not very practical as oil viscosity changes depending on the geology and geographical location. If spiral flow technique is adopted universally in the correct way, it will help to reduce the amount of investment as well as man power to achieve better results.

Researchers have used various different types of chemical inhibitors, such as polyethylene, ethylene/vinyl acetate copolymers, copolymer esters [24][32][31], ester/vinyl acetate copolymers, olefin/ester copolymers, polymethacrylates [33] [34][35][36], alkyl phenol resins, xylene and toluene [24][37] [38], studying their effects on wax appearance temperature, wax content, pour point, and crude oil viscosity using analytical methods, to evaluate the suitable inhibitor for the waxy crude oil that provides the desired results in preventing wax deposition.

A small number of researchers have used an experimental flow loop to study and determine dynamically the efficiency of wax inhibitors on wax deposition inside the pipe, such as some of them are [29][30], [39].

The difference between the analytical methods and the experimental flow loop systems is the experimental conditions used in the flow loop deposition test affected the performance of paraffin inhibitors, indicating that temperature gradients (i.e., oil temperature and inlet coolant temperature) must be optimized to achieve the highest reduction in wax deposition. While, the experimental conditions in the analytical methods can be controlled, such as pressure, temperature, and shear rate, providing accurate results in the analytical of wax inhibition [40].

[29] investigated the effect of chemical inhibitors such as poly(ethylene-co-vinyl acetate) (EVA) and poly(maleic anhydridealt-1-octadecene) (MA) on wax deposition, using cold finger apparatus. The wax inhibition percentage of their study was 23.1% using EVA and 7.5% using MA at a coolant temperature of 25°C. Adeyanju and Oyekunle (2014) [30] investigated the effect of groups of acrylate ester copolymers of varying alkyl side chains as wax inhibitors during the flow of crude oil in the flow loop. Wax inhibition percentages of 25-55% were obtained at high coolant temperatures above 20°C at a concentration of 5000ppm of the inhibitor. Hoffmann and Amundsen (2013) [39] found that about 60%-90% of wax thickness was reduced by applying different concentrations (125, 250 and 500ppm) of the commercial inhibitor, and using silicon as an insulation material during experimental work investigation.

In the previous studies, even though many different types of chemical inhibitors have been used at different concentration, at different inlet coolant temperatures, there is still wax deposit on the pipe wall due to the researchers missed investigate the effect of combining the chemical inhibitors on wax deposition.

A small number of researches mentioned using the spiral flow and studied its effects in different areas [41] [42][43][44][45] [46][47], however, Theyab and Diaz (2016a, 2016b, 2016c) [5][6][7] were used the technique of spiral flow for the first time as a wax mitigation method. They built an experimental rig to study the wax deposition thickness under the single phase and to study the impact of some factors, such as flow rate, pressure drop, inlet coolant temperature, crude oil temperature, oil viscosity, time, shear stress, Polyacrylate polymer [48] and spiral flow, that influence and control on wax deposition process. The spiral flow was generated by inserting a twisted plate inside the pipe and examined in the test section of the pipe in order to increase the shear rate and shear dispersion and mitigate wax deposition [49]. The results illustrated that the reduction in wax deposition was 100% after using the influence of bending spiral flow with polyacrylate polymer at a concentration of 1000 ppm and 2000 ppm at different time and flow rates. The reduction in wax deposition was 100% after using the effect of bending the spiral flow with the inhibitor at a concentration of 500 ppm at flow rate 4.8 L/min, and the reduction in wax deposition was 94% at the same concentration and flow rate 2.7 L/min.

Conclusions

According to the previous studies mentioned in this work, it can be concluded:

- Many oil companies prefer chemical inhibitors in cold environments, considering this economic way and best solution to reduce wax deposition in pipelines due to chemical additives does not need to stop production for cleaning the pipe but it considers as an online mitigation method.

- There is currently no universal type of inhibitor that can be used for all kinds of crude oil due to the varying properties of crude oils, because of the universal inhibitor may solve the wax deposition problem and create more problems such as (corrosion) due to varying properties of crude oils and the different climate.

- It needs to undertake a systematic study of inhibition of wax deposition using chemicals and combinations of chemicals.

- Raise interest in the possibility of increasing the shear rate to prevent wax deposition, using spiral flow as a way to increase shear rate in the flow.

- Undertake a systematic study of inhibition of wax deposition using the effects of combination spiral flow with a chemical inhibitor.

References

- Singh P, Venkatesan R, Fogler HS, Nagarajan N. Formation and aging of incipient thin film wax-oil gels. AIChE. 2000; 46(5): 1059-74. doi: 10.1002/ aic.690460517

- Lee HS. Computational and Rheological Study of Wax Deposition and Gelation in Subsea Pipelines. PhD Thesis, University of Michigan, 2008.

- Nguyen DA. Fused chemical reactions to remediate paraffin plugging in sub-sea pipelines. Ph.D. Thesis, University of Michigan, 2004.

- Matthew M. Offshore oil production in deepwater and ultradeepwater is increasing, [ONLINE] Available at: https://www.eia.gov/todayinenergy/ detail.php?id=258552#. [Accessed 21 May 2017].

- Theyab MA, Diaz P. Experimental study of wax deposition in pipeline – Effect of inhibitor and spiral flow. International Journal of Smart Grid and Clean Energy. 2016a; 5: 174-181. doi: 10.12720/sgce.5.3.174-181

- Theyab MA, Diaz P. Experimental study on the effect of spiral flow on wax deposition thickness, one petro, presented at SPE Russian Petroleum Technology Conference and Exhibition, Moscow, Russia, SPE 181954-MS, 2016.

- Theyab MA, Diaz P. Experimental study on the effect of spiral flow on wax deposition volume, one petro, presented at Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, UAE, SPE-182936-MS, 2016.

- Huang Z, Zheng S, Fogler HS. Wax Deposition: Experimental Characterizations, Theoretical Modeling, and Field Practices. USA: Taylor & Francis Group. LLC, Version Date: 20150408, ISBN-13: 978-1-46656767-2, 2015.

- Bern PA, Withers VR, Cairns JR. Wax deposition in crude oil pipelines, in: Proc European Offshore Petroleum Conference and Exhibition, London, England, October 21-24. Available from: https://0-www.onepetro.org. lispac.lsbu.ac.uk/download/conferencepaper/SPE-206-1980- MS?id=c11onference-paper%2FSPE-206-1980-MS [Accessed 19 February 2013].

- Trina S, Johansen T. An Integrated Horizontal- and Vertical Flow Simulation With Application to Wax Precipitation. Society of Petroleum Engineers. 2015; 20(6). doi: 10.2118/156555-PA

- Botne KK. Modelling wax thickness in single-phase turbulent flow. MSc thesis, Norwegian University of Science and Technology, Department of Petroleum Engineering and Applied Geophysics.Available from: http:// daim.idi.ntnu.no/masteroppgaver/007/7848/masteroppgave.pdf [Accessed 8 January 2013].

- Kjøraas. Modelling of Wax Deposition in Subsea Pipelines, Norwegian University of Science and Technology, Department of Petroleum Engineering and Applied Geophysics, 2012.

- Siljuberg MK. Modelling of Paraffin Wax in Oil Pipelines, NTNUTrondheim, July 2012.

- Tordal A. Pigging of Pipelines with High Wax Content. Publication of Pigging Products and Services Association, Statoil ASA, Stavanger, Norway. Available from: http://www.ppsaonline.com/papers/2006- Aberdeen-1-Tordal.pdf [Accessed 14 January 2014].

- Zhu T, Walker JA, Liang J. Evaluation of Wax Deposition and Its Control during Production of Alaska North Slope Oils. Final Report, University of Alaska Fairbanks, ConocoPhillips Alaska, Inc., University of Kansas, United States Department of Energy National Energy Technology Laboratory, Oil & Natural Gas Technology, DOE Award No.: DE-FC26-01NT41248, 2008.

- Singhal HK, Sahai GC, Pundeer GS, Chandra K. Designing and Selecting Wax Crystal Modifier for Optimum Field Performance Based on Crude Oil Composition, 66th Annual Technical Conference and Exhibition, Dallas, Texas, USA, October 6-9, 1991.

- Salam KK, Arinkoola AO, Oke EO, Adeleye JO. Optimization of Operating Parameters using Response Surface Methodology for Paraffin-Wax Deposition in Pipeline. Petroleum & Coal. 2013; 56(1): 19-28.

- Adeyanju OA, Oyekunle LO. Experimental Study of Wax Deposition in a Single Phase Sub-cooled Oil Pipelines, in: The Nigeria Annual International Conference and Exhibition, University of Lagos, Nigeria, 30 July - 1 August, pp. 1-18. Available from: https://0www.onepetro.org.lispac.lsbu.ac.uk/ download/conference-paper/SPE167515-MS?id=c1921onferencepaper%2FSPE-167515-MS [Accessed 27 August 2016].

- Akpabio MG. Cold Flow in Long-Distance Subsea Pipelines. MSc Thesis, Norwegian University of Science and Technology, 2013.

- Woo GT, Garbis SJ, Gray TC. Long-Term Control of Paraffin Deposition, SPE Annual Technical Conference and Exhibition, Houston, September 16-19, 1984.

- a. Bott TR, Gudmunsson JS. Deposition of Paraffin Wax from Kerosene in Cooled Heat Exchanger Tubes. Canadian Journal of Chemical Engineering. 1984; 55(4): 381-3 85. doi: 10.1002/cjce.5450550403

b. Bland JM, Altman DG. Statistics notes: measurement error. BMJ. 1996; 312(7047): 1654. doi: 10.1136/bmj.312.7047.1654 - White FM. Fluid Mechanics. Sixth Edition. Amazon: McGraw-Hill, 2008.

- Aiyejina A, Chakrabarti DP, Pilgrim A, Sastry MKS. Wax formation in oil pipelines: A critical review. International Journal of Multiphase Flow. 2011; 37(7): 671-694. Doi: 10.1016/j.ijmultiphaseflow.2011.02.007

- Kang PS, Lee DG, Lim JS. Status of Wax Mitigation Technologies in Offshore Oil Production, in: International Society of Offshore and Polar Engineers Conference, Busan, Korea, June 15-20, pp. 31-38. Avaiable from: https://0-www.onepetro.org.lispac.lsbu.ac.uk/download/conferencepaper/ISOPE-I14-285?id=c2528onference-paper%2FISOPE-I-14-285[Accessed 11 August 2015].

- Craddock HA, Mutch K, Sowerby K, McGregor S, Cook J, et al. A Case Study in the Removal of Deposited Wax From a Major Subsea Flowline System in the Gannet Field, SPE 105048 presented at SPE International Symp in Oilfield Chemistry, Houston, 2007.

- Goodman NT, Joshi N. A Tale of Two Flowlines-Paraffin Plugging and Remediation, SPE 166196 presented at SPE Annual,Tech Conf and Exh, New Orleans, 2013.

- Struchkov IA, Rogachev MK, Kalinin ES, Pavlov PV, Roschin PV. Laboratory Investigation of Organic-Scale Prevention in a Russian Oil Field. Society of Petroleum Engineers. 2017; 33(1). doi: 10.2118/185961PA

- Kok MV, Saracoglu O. Mathematical Modelling of Wax Deposition in Crude Oil Pipeline Systems. Society of Petroleum Engineers, 2000. doi: 10.2118/64514-MS

- Ridzuan N, Adam F, Yaacob Z. Molecular Recognition of Wax Inhibitor through Pour Point Depressant Type Inhibitor. International Petroleum Technology Conference. 2014. doi: 10.2523/17883-MS

- Adeyanju OA, Oyekunle LO. Influence of Long Chain Acrylate Ester Polymers as Wax Inhibitors in Crude Oil Pipelines. Society of Petroleum Engineers. 2014. doi: 10.2118/172844-MS

- Halim N, Ali S, Nadeem MN, Abdul Hamid P, Tan IM. Synthesis of Wax Inhibitor and Assessment of Squeeze Technique Application for Malaysian Waxy Crude. Society of Petroleum Engineers. 2011. doi: 10.2118/142288- MS

- Jafari Ansaroudi HR, Vafaie-Sefti M, Masoudi S, Behbahani TJ, Jafari H. Study of the Morphology of Wax Crystals in the presence of Ethylene-covinyl Acetate Copolymer. Pet. Sci. Technol. 2013; 31(6): 643-651. doi: 10.1080/10916466.2011.632800

- Wu Y, Ni G, Yang F, Li C, Dong G. Modified Maleic Anhydride Co-polymers as Pour-Point Depressants and Their Effects on Waxy Crude Oil Rheology. Energy and Fuels. 2012; 26(2): 995-1001. doi: 10.1021/ef201444b

- Al-Sabagh AM, Noor-El-Din MR, Morsi RE, Elsabee MZ. Styrene-Maleic Anhydride Copolymer Ester as Flow Improvers of Waxy Crude Oils. Journal of Petroleum Science and Engineering. 2009; 65(3-4): 139-146. doi: 10.1016/j.petrol.2008.12.022

- Han S, Song Y, Ren T. Impact of Alkyl Methacrylate-Maleic Anhydride Copolymers as Pour Point Depressant on Crystallization Behaviour of Diesel Fuel. Energy and Fuel. 2009; 23(5): 2576-2580. doi: 10.1080/10916460903058210

- Duffy DM, Rodger PM. Modeling the activity of Wax Inhibitors: A Case Study of Poly (octadecyl acrylate). The Journal of Physical Chemistry B. 2002; 106(43): 11210-11217. doi: 10.1021/jp026501j

- Jennings DW, Newberry ME. Paraffin Inhibitor Applications in deepwater Offshore Development, in: The International Petroleum Technology Conference, Kuala Lumpur, Malaysia, 3-5 December. Available from: https://0- www.onepetro.org.lispac.lsbu.ac.uk/download/conferencepaper/IPTC12127-MS?id=c3742onference-paper%2FIPTC-12127-MS [Accessed 24 January 2013].

- Jang YH, Blanco M, Creek J, Tang Y, Goddard WA. Wax Inhibition by Comb-like Polymers: Support of the IncorporationPerturbation Mechanism from Molecular Dynamics Simulations. J. Phys. Chem. B. 2007; 111(46): 13173-13179. doi: 10.1021/jp072792q

- Hoffman R, Amundsen L. Single-Phase Wax Deposition Experiments. Energy & Fuels. 2010; 24(2): 1069-1080. doi: 10.1021/ef900920x

- Perez P, Boden E, Chichak K, Gurnon AK, Hu L, et al. Evaluation of Paraffin Wax Inhibitors: An Experimental Comparisonof Bench-Top Test Results and Small-Scale Deposition Rigs for Model Waxy Oils, in: Offshore Technology Conference, Houston, Texas, USA, 2015.

- Xie L. Hydraulic Engineering. London: Taylor and Francis Group, ISBN 978- 1-138-00043-8, 2013.

- Betül AS, Tulin B. An Experimental Study on Heat Transfer and Pressure Drop Characteristics of Decaying Swirl Flow through a Circular Pipe with a Vortex Generator. Experimental Thermal and Fluid Science. 2007; 32: 158- 165. doi: 10.1016/j.expthermflusci.2007.03.002

- Li Y. Sun X, Yan Q. Experimental study on the characteristics of spiral flow in a local generator. Journal of Hydroelectric Engineering. 2011; 30(2): 72-77.

- Zhang Y, Zhang XE, Peng LS. Experimental Study on Sediment Transportation of Spiral Flow in Pipe. Journal of Sediment Research. 2005; 2: 34-38.

- Zhang Y, Peng L, Li Z. Rotation-starting of Sediments in Spiral Flow in the Horizontal Pipe. Journal of Sediment Research. 2005; 2: 71-75.

- Zhang XE, Sun XH, Huo DM. The Numerical Simulation of Spiral Flow Field with Continuous Guiding Vane. Journal of Taiyuan University of Technology. 2001; 32: 252-254.

- Liu Y, Huang Z, Hoffmann R, Amundsen L, Fogler HS, et al. Counterintuitive effects of the oil flow rate on wax deposition. Energy & Fuels. 2012; 26(7): 4091-4097. doi: 10.1021/ef3002789

- Theyab MA, Diaz P. Experimental study on the effect of polyacrylate polymer (C16-C22) on wax deposition. International Journal of Chemical Engineering and Applications. 2016d; 8: 16-21. doi: 10.18178/ijcea.2017.8.1.624

- Theyab MA. Experimental Methodology Followed to Evaluate Wax Deposition Process. J Pet Environ Biotechnol. 2018; 9: 357. doi:10.4172/2157-7463.1000357