Research Article

Microwave assisted pyrolysis of Imperata Cylindrica with ionic liquids pre-treatment

1Department of Chemical Engineering Technology, Faculty of Engineering Technology, Universiti Malaysia Perlis, Kampus Unicity Sungai Chuchuh, Padang Besar, 02100 Perlis, Malaysia

3School of Chemical Engineering, Engineering Campus, Universiti Sains Malaysia, 14300 Nibong Tebal, Penang, Malaysia

3Solid Waste Management Cluster, Science & Engineering Research Centre, Engineering Campus, Universiti Sains Malaysia, Nibong Tebal, Penang, Malaysia

*Corresponding author: Mohd Azmier Ahmad, Associate Professor, School of Chemical Engineering, Engineering Campus, Universiti Sains Malaysia, 14300 Nibong Tebal, Penang, Malaysia, Tel: +604 5996459, Fax: +604 5996908, E-mail: chazmier@usm.my

Received: March 28, 2017 Accepted: April 27, 2017 Published: May 3, 2017

Citation: Kefli AA, Khasri A, Rohaizad NM, Ahmad MA. Microwave assisted pyrolysis of Imperata Cylindrica with ionic liquids pre-treatment. Int J Petrochem Res. 2017; 1(1): 73-75. 10.18689/ijpr-1000112

Copyright: © 2017 The Author(s). This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Pyrolysis of Imperata Cylindrica via microwave irradiation pre-treated with 1-butyl-

3-methyl-imidazolium tetrafluoroborate (IL-B) and 1-butyl-3-methyl-imidazolium chloride (IL-C) as ionic liquids (ILs) were investigated. The effect of operating variables; microwave

power, particle size and IL: biomass mass ratio (MR) towards bio-oil yield were studied. At constant heating time of 20 min and nitrogen flowrate of 2L/min, the optimum

pyrolysis conditions of microwave power, particle size and MR were obtained at 700 W, = 300 μm and 0.3, respectively. At this point, pyrolysis Imperata Cylindrica pretreated by

IL-B and IL-C have resulted bio-oil yield of 19.07% and 16.21%, respectively.

Keywords: Biomass, Bio-oil, Imperata Cylindrica, Ionic liquid, Microwave, Pyrolysis

Introduction

Presently the fossil fuel resources supplies are falling off and this situation has created

strong attraction in finding other option particularly from renewable biomass sources as

alternative energy source. Biomass contains stored energy and can be converted to pyrolysis

liquids known as the bio-oils through pyrolysis process [1]. Biomass pyrolysis is defined as

the thermal decomposition of the biomass organic matrix which resulted bio-oil, char and

gas as products [2]. Particularly bio-oil has been suitable candidates to replace petroleum

fuels to be used in various thermal devices. Bio-oil is a kind of hydro carbon with dark brown

colour, free flowing liquids with smoky odour. They are complex mixtures of compounds

that are derived from the depolymerization of cellulose, hemicellulose and lignin [3].

A number of conventional pyrolysis technologies have been developed such as

fixed bed reactor [4], vacuum pyrolysis reactor, transport bed, bubbling fluid bed, circulating fluid bed and rotating cone. However, these technologies are using external

heat source which requires high energy consumption and long processing time [5]. In

this study, an attempt was made in using microwave heating for pyrolysis of Imperata

Cylindrica as biomass. In addition, ILs were used for pre-treatment of the biomass for

accelerating the bio-oil production during the microwave heating.

Materials and methods

Raw material and catalyst

The biomass feed stock of Imperata Cylindrica or cogon grass used in this study was

obtained from Perlis, Malaysia. The sample was cut into small pieces and dried for 8 hours at

100°C in an oven. Then, the samples were milled and sieved into three different ranges of

particle sizes of = 300μm, 300-425μm and 425-600μm.The proximate analysis was carried out using thermogravimetric analyzer (Perkin Elmer TGA7, USA). The elemental analysis was performed using Elemental Analyzer (Perkin Elmer Series II 2400, USA). Extractives, hemicelluloses, lignin and cellulose concentration of Imperata Cylindrica are

shown in Table 1.

Table 1: Proximate, ultimate and component analysis of Imperata Cylindrica

1-butyl-3-methyl-imidazolium tetrafluoroborate and 1-butyl- 3-methyl-imidazolium chloride supplied by Merck (M) Sdn. Bhd with purity of 99% were used without any further purification.

Pre-treatment of ILs

Before pyrolysis process,the Imperata Cylindrica was

pre-treated with IL aqueous solution. For IL to biomass mass

ratio (MR) of 0.1, IL aqueous solution was prepared by

dissolving 1.0 g of IL-B or IL-C into 34 mL of distilled water. 10

g of Imperata Cylindrica was immersed in the IL aqueous

solution followed by heating at 80°C for 2 hours. Using the

same procedures, various MR were prepared by changing the

amount of IL added in distilled water.

Microwave-assisted pyrolysis process

The schematic diagram of the apparatus set-up isshown in

Figure 1. The pyrolysis of biomass was carried out using a

modified commercial microwave with a frequency of 2.45 GHz. The quartz tube reactor with 6 cm internal diameterand14 cm

height was installed in the cavity of the microwave. The microwave

was equipped with two condensers in series to cool down the

vapour generated during pyrolysis process. 5g of the pre-treated

biomass was placed into the quartz tube reactor. The N2 gas was

purged for 5 minutes at 2 L/min to ensure inert condition of the

system. All experiments were conducted using heating time of

20 minutes and N2 gas flowrate of 2 L/min. The bio-oil produced

was collected in a conical flask. For study the effect of microwave

power, particle size of less than 300μm and MR of 0.3 were used. For study the effect of particle size, microwave power and MR of

700 W and 0.3 were used. For study the effect of MR on bio-oil

yield, the microwave power of 700 W and particle size of less

than 300μm were used.

Figure 1: Schematic layout of microwave pyrolysis experimental setup

Results and discussion

Effect of microwave power and particle sizes on pyrolysis of Imperata Cylindrica

Figure 2 shows the distribution of products yield using various microwave power. The yield of solid char was the highest followed by gas and bio-oil products. The bio-oil yield first increased and then decreased with an increase in microwave power (Fig.2). The maximum yield of bio-oil of 15.3% was obtained at 700 W and decreased to 12.5% at 800 W. The pyrolysis reaction is an endothermic process, so the yield of the bio-oil increased by raising the microwave power. This is because as microwave power increased, more strong organic bonds in the sample were broken [6]. However, the bio-oil yield was decreased at 800 W due to secondary thermal decomposition of some of the compounds of bio-oil yielding gaseous product under higher power [7]. Therefore, the gas yield substantially increased but the liquid yield substantially decreased with increasing microwave power, whereas the reduction in the solid char yield was not so obvious. This may imply that, when product vapors are released by the devolatilization of biomass pyrolysis, more hydrocarbons in the vapors can be converted into permanent gases at higher power.

Figure 2: Effect of microwave power on product yield

Figure 3 shows the effect of particle sizes on the product distribution using microwave power at 700 W.It can be seen that char and bio-oil yields decreased where as gas yield increased as the particle size increased up to 425-600 μm. The maximum bio-oil yield of 13.9% was obtained at particle size less than 300 μm. This is due to the fact that smaller particles promote the heat and mass transfer to form uniform temperature within particles during pyrolysis, thereby enhancing the bio-oil production and secondary cracking of solid residue by restraining the vapour formation. At lower particle size ranges, more residence time of volatiles inside the reactor results in the heavier molecules cracking in to lower molecules and thus lead to rise of gaseous product [4]. Larger particles will heat up more slowly compared to small particles, so the average particle temperature is lower and hence affects the product yield. Particle size less than 300μm and microwave power of 700 W, which gave the highest biooil yield were used in the following section.

Figure 3: Effect of particle size on product yield

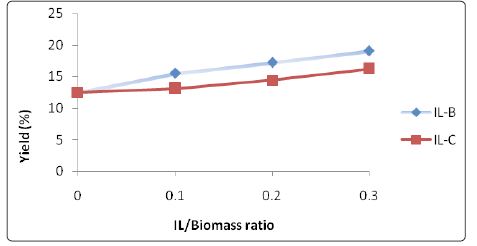

Effect of MR on pyrolysis of Imperata Cylindrica

Figure 4 shows that lowest bio-oil yield produced without

IL under microwave heating indicates that the presence of ILs

showed positive effect on the bio-oil yield. This is due to the

capability of ILs to adsorb microwave energy effectively, leading to rapid rise of reaction temperature and the

promotion of biomass pyrolysis and thus results in increased

of bio-oil yield. Furthermore, the pre-treatment has been

trialled to reduce the lignin content, generally the most

thermally resistant compound in the lingo cellulosic biomass, so that the pyrolysis bio-oil yields can be enhanced. Lateef et

al. stated that ILs could interact with terminal OH groups of

lignin, subsequently disrupting the internal network within

the lignin molecule, resulting in the dissolution of lignin [8]. As

can be seen in the figure, both ILs have shown increase pattern

when the MR was increased. However, IL-B shows better

performance than IL-C in producing bio-oil. The bio-oil yield

produced for IL-B and IL-C were between 15.54 to 19.07% and 13.12 to 16.21%, respectively. Although both ionic liquids

possessed the same cation but different anion (Cl- and BF4

-). In

addition, IL-B anion was found to be more efficient in the

depolymerization of cellulose and hemicelluloses during the

pretreatment step thus more bio-oil was produced compared

to IL-C [9]. Therefore, it can be concluded that anions of ILs

have important effect on the dissolution of cellulose, hemicellulose and lignin component [10].

Figure 4: Effect of MR on bio-oil yield

Conclusion

The optimum conditions for pyrolysis of Imperata Cylindrica using microwave heating which pre-treatment with two ILs were obtained. Under the optimum conditions of microwave power of 700 W, particle size less than 300μm and MR of 0.3, the maximum bio-oil yield of 19.07% 16.21% for sample treated with IL-B and IL-C, respectively.IL-B shows better performance than IL-C in producing bio-oil. This study shows that the pre-treatment of biomass using ILs prior to pyrolysis had successfully increased the bio-oil yield. Thus, ILs pretreatment showed optimistic outcome on the pyrolysis of biomass under microwave heating.

Acknowledgements

This research was supported by Ministry of Higher Education, Malaysia (MOHE) under Fundamental Research Grant Scheme (FRGS) through the project number 9003-00382.

References

- McKendry P. Energy production from biomass (part 1): Overview of biomass. Bio Res Tech. 2002; 83(1): 37-46. doi: 10.1016/S0960- 8524(01)00118-3

- Tao K, Vladimir S, Tim JE. Lignocellulosic biomass pyrolysis: A review of product properties and effects of pyrolysis parameters. Renewable and Sustainable Energy Reviews. 2016; 57: 1126-40. doi: 10.1016/j. rser.2015.12.185

- Lu Q, Li WZ, Zhu XF. Overview of fuel properties of biomass fast pyrolysis oils. Energy Conversion and Management. 2009; 50(5): 1376-83. doi: 10.1016/j.enconman.2009.01.001

- Azduwin K, Ridzuan MJM, Hafis SM, Amran T. Slow pyrolysis of ImperataCylindrica in a fixed bed reactor. Int J Biol Ecol Envir Scien. 2012; 1(5): 176-80.

- Salema AA, Ani FN. Microwave-assisted pyrolysis of oil palm shell biomass using an overhead stirrer. J. Anal. Appl. Pyrol. 2012; 96: 162-72. doi: 10.1016/j.jaap.2012.03.018

- Du J, Liu P, Liu ZH, Sun DG, Tao CY. Fast pyrolysis of biomass for bio-oil with ionic liquid and microwave irradiation. Fuel Chem Tech J. 2010; 38(5): 554-59. doi: 10.1016/S1872-5813(10)60044-8

- Motasemi F, Afzal MT. A review on the microwave-assisted pyrolysis technique. Energy and Sustainable Energy Reviews. 2013; 28: 317-30. doi: 10.1016/j.rser.2013.08.008

- Lateef H, Grimes S, Kewcharoenwong P, Feinberg BJ. Separation and recovery of cellulose and lignin using ionic liquids: a process for recovery from paper-based waste. Chem. Technol. Biotechnol. 2009; 84(12): 1818-27. doi: 10.1002/jctb.2251

- Muhammad N, Omar WN, Man Z, Bustam MA, Rafiq S, Uemura Y. Effect of ionic liquid treatment on pyrolysis products from bamboo. Ind. Eng. Chem. Res. 2012; 51(5): 2280-89. doi: 10.1021/ie2014313

- Wang J, Zheng Y, Zhang S. The application of ionic liquids in dissolution and separation of lignocellulose, in: K. Eguchi (Ed.). Clean Energy Systems and Experiences, InTech. 2010; 71-84.